Powerful and extremely miniaturised

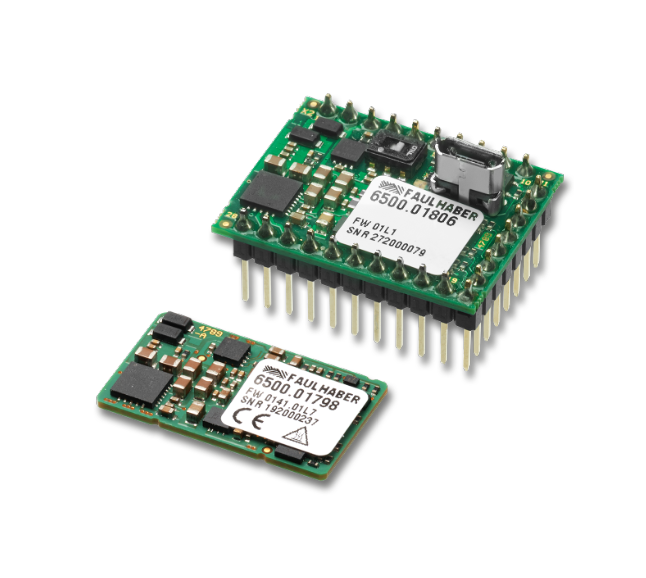

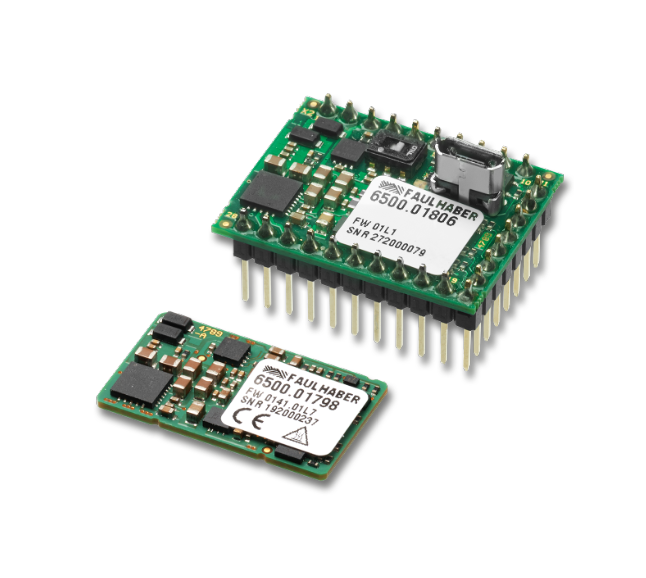

With the new MC3001 motion controllers, available as MC 3001 B (board-to-board connectors) or MC3001P (28-pin plug connector), FAULHABER completes the MC V3.0 generation of controllers for smaller motor series.

The controllers are extremely miniaturised and, with 1.4 amperes in continuous operation and up to 5 amperes peak current, are very powerful. They are designed as slaves for control and positioning tasks of DC-micromotors, linear DC servomotors or brushless DC-motors.

The new MC 3001 are unhoused versions of the FAULHABER motion controllers and, by means of the integrated output stage with optimized current measurement, can control DC-micromotors, linear DC-servomotors or brushless DC-motors from the FAULHABER product line from 6 to 30 millimeters. They are configured here via the FAULHABER Motion Manager software V6 (version 6.8 and higher). The very good EMC behaviour of the new motion controllers has been certified by external laboratories.

zástavbových rozměrů a nekompromisními požadavky na řízení.

Technical Data | MC 3001 B/P | |

Electronic supply | 6...30 | V |

Motor supply | 6...30 | V |

Max. continous output current | 1 (B) / 1,4 (P) | A |

Temperature range | -40...+85 | °C |

Dimensions | 16x27 (B) / 23x30 (P) | mm |

Peak current | 5 | A |

Mass | 2/5 | g |

For configuration via | Motion Manager 6.8 | - |

For combination with | DC, BL, and LM motors | - |

Interface | RS232, CANopen, USB | - |